Better By Design

At Andover Trailers, we engineer premium transport solutions built to perform and last. With decades of experience and a focus on quality, we remain the standard others aspire to.

From plant bodies to step frames and specialist builds, we manufacture trailers built to your exact needs.

We offer a fleet of high-quality trailers for short or long-term rental across the UK.

From scheduled maintenance to nationwide parts support, we're here to keep your fleet running at its best.

On-site or at our partner garages across the UK.

Genuine OEM and compatible parts with fast delivery.

We deliver expert servicing and support wherever you operate across the UK

Every AndoverX trailer represents a leap forward in innovation and reliability. Whether you're hauling heavy equipment or operating in extreme environments, the AndoverX range is built to exceed expectations.

See our trailers in operation, learn about our products' features and discover what sets Andover Trailers apart.

Whether you're looking for a custom build, need assistance with servicing, or want to learn more about our trailers — our friendly team is just a call or click away.

Established in 1985, Andover Trailers has grown to become the standard to which others aspire within specialist body and trailer manufacturing. We use our unrivalled experience to design products that meet our customer's needs perfectly. That means understanding the role of your fleet to design and build a product which is tailor-made to deliver value to you both now and into the future.

Every plant body or trailer that leaves our factory is truly BETTER BY DESIGN

We begin by understanding your exact needs to deliver a tailored solution with clear, transparent pricing.

Our experienced engineers develop custom specifications, ensuring every detail is built around your operation.

Our UK-based facility crafts each trailer using robust materials and leading technology.

Every unit undergoes detailed inspections and functional testing before sign-off.

After a final walkthrough, your trailer is delivered or collected — ready for years of reliable service.

We adhere to the highest industry standards, backed by key certifications and third-party approvals.

Since 1985, we've been pushing the boundaries in specialist trailer and body manufacturing with a commitment to quality and ingenuity.

All our trailers are built at our UK facility and trusted by operators across industries both nationally and internationally.

Each product is tailored to meet your unique operational demands, providing long-term value and performance.

Take a look inside our workshop and see how your trailers come to life.

Our friendly team is always here to help you!

With over 40 years of industry experience, our expert team stands at the heart of Andover Trailers' reputation for quality and innovation.

Every year, we design and build more than 200 bespoke trailers and plant bodies, delivering precision-engineered solutions trusted across the UK. Our long-standing success is built on deep technical knowledge, an unwavering commitment to customer satisfaction, and a proven track record in meeting the complex demands of specialist transport.

Find your dream job today!

There are currently no vacancies available. Please check later.

Even if the perfect role isn’t listed, we’re always on the lookout for skilled, motivated people to join our team.

Discover our full range of specialist trailers, each built with precision and tailored to meet the most demanding requirements in transport and logistics.

Our versatile step frame trailers are designed for superior payload handling and load stability.

Ideal for transporting equipment with low ground clearance — our sloping decks reduce approach angle with precision engineering.

Low-height trailers built for heavy and oversized machinery transport, with customizable deck options.

Built to securely carry industrial forklifts and material handlers. Safe, stable, and proven in the field.

Compact yet capable. Our drawbar trailers are ideal for short-haul transport, built with strength and simplicity in mind.

Offering payloads from 26 to 74 tonnes and two to five axles, the range of Andover Trailers step frame trailers are the workhorses of the plant, construction and heavy haulage industries.

Defined by their low deck heights, low profile neck and ease of operation, the step frame range offers a wide choice of options to bespoke build a trailer to suit your requirements.

All models are engineered for concentrated loads, available for C&U and STGO use, and feature maximised lower deck length. From fixed to extending lengths and a huge array of axle and ramp configurations, these trailers are built without compromise.

| Model | Axles | Gross Trailer Weight* | Approx Payload* |

|---|---|---|---|

| SFCL32 | 2 | 32t | 26t |

| SFCL36 | 3 | 36t | 29t |

| SFCL48 | 3 | 48t | 38t |

| SFCL56 | 3 | 59.5t | 48t |

| SFCL73 | 4 | 73t | 58t |

| SFCL85 | 5 | 90t | 74t |

* Payload dependent on final trailer specification.

Our experienced sales team is here to guide you through the options and tailor a solution to fit your needs.

Call Us: 01264 358 944Designed to precisely match the requirements of the road maintenance sector, operators of the range of sloping deck step frame trailers – also known as semi-slopers or sloping bed trailers – are finding their low loading angles and ease of operation useful for many more varied loads.

Available in two- and three-axle versions, with payloads up to 36 tonnes, the sloping deck allows access to the full length of the bed by machines with lower ground clearance, such as road rollers and paving machines.

Whether for versatility or to suit a particular load, the options list is vast. Custom lashing points and a range of ramp designs are just the start of the wide range of options available to tailor a sloping bed trailer to your requirements.

| Model | Axles | Gross Trailer Weight* | Approx Payload* |

|---|---|---|---|

| SFSL32 | 2 | 32t | 26t |

| SFSL36 | 3 | 36t | 29t |

| SFSL44 | 3 | 44t | 36t |

* Payload dependent on final trailer specification.

Speak to our expert team for tailored advice and availability.

Call Us: 01264 358 944Our hydraulic detachable-neck low loaders are engineered to move combination weights from 28 to 150 tonnes with confidence.

You can choose non-steered, friction-steered with self-tracking axles, or full power-steering versions, and operate them with or without dollies to match your tractor units and payload demands.

These trailers are trusted to haul heavy loads in some of the world's toughest environments, a testament to their strength, reliability and quality. Power-steered models feature industry-leading hydraulic systems for effortless manoeuvring.

Each unit is made to measure, with options such as deck length and width variations, axle configurations, side extensions, and a rear beavertail with matched ramps. Every trailer is built to your exact specification, delivering the right balance of capacity, versatility and durability—so get in touch and let's design a low loader that moves your business forward.

| Model | Axles | Gross Trailer Weight* | Approx Payload* |

|---|---|---|---|

| TBD | TBD | TBD | TBD |

* Payload dependent on final trailer specification.

Speak to our expert team and start building your low loader today.

Call Us: 01264 358 944Andover Trailers' forklift transporters set the benchmark for safe, reliable movement of even the tallest-mast machines and are trusted by leading materials-handling manufacturers and distributors worldwide.

To match the equipment you move, we build two distinct designs:

Both variants come with full-width, single-piece or power-toe ramps that provide an exceptionally shallow loading angle for low-ground-clearance forklifts, plus an array of load-securing points to keep every journey safe. Step-frame models can also be specified with a lifting floor for easy access to the neck.

Trailers may be supplied open or bodied with TSE's all-steel sliding-roof system—renowned for strength and the ability to travel safely while the roof is retracted. Curtainsider or GRP bodies are also available to meet your exact operational needs.

| Model Step Frame | Model Wheel Box | Axles | Gross Trailer Weight* | Approx Payload* |

|---|---|---|---|---|

| SFCL32 | FKWB32 | 2 | 32t | 26t |

| SFCL36 | FKWB36 | 3 | 36t | 29t |

* Payload dependent on final trailer specification.

Contact our specialist team to tailor one for you today.

Call Us: 01264 358 944We build drawbar trailers from 8 to 25 tonnes in both conventional turntable and centre-axle formats, giving you a versatile solution for plant transport and specialist applications.

Trailers intended for concentrated loads can be tailored with the same proven options found on our step-frame plant range—plus drawbar-specific features such as front ramps for through-loading onto the prime mover.

For distributed-load work, drawbars can be supplied with your choice of body—curtainsider, dropside, box, or more—or delivered as a bare chassis, ready for your bodybuilder to finish.

Alongside general plant carriers, we design application-specific drawbars that showcase Andover Trailers' innovation: by blending advanced materials we achieve ultra-low unladen weights, maximising your payload and profitability.

| Model | Axles | Gross Trailer Weight* | Approx Payload* |

|---|---|---|---|

| CBDB12 | 2 | 12t | 8t |

| CBDB19 | 2 | 19t | 15t |

| CBDB25 | 3 | 25t | 20t |

* Payload dependent on final trailer specification.

Contact our specialist team to tailor one for you today.

Call Us: 01264 358 944The AndoverX range represents a new generation of lightweight and ultra-lightweight trailers, developed to maximise payload without compromising strength, safety or durability.

Manufactured in partnership with Emtech in Poland, these trailers are engineered using modern materials and design principles that reduce unladen weight—allowing you to carry more while using less.

The range includes a variety of flatbed and beavertail trailers, with precise axle configurations and load-handling solutions tailored to general haulage, recovery, and plant transport operations.

AndoverX trailers deliver high efficiency, low operating costs, and exceptional ease of use, all wrapped in a contemporary European design.

Contact our specialist team to tailor one for you today.

Call Us: 01264 358 944Our plant bodies are among the best in the industry, with deck heights up to five inches lower than standard. Custom-built to suit your chassis, they offer optimal ramp and beavertail angles. We work with all major European truck brands to maximise suspension and tyre tech for low loading angles, stability, and safety.

Available from 7.5 to 32 tonnes, with or without cranes, our range includes the widest choice of options—like fold-forward or cheese-wedge ramps. From mini diggers to bulldozers, we've got the right body for your load.

We work closely with all major European truck manufacturers, including Volvo, Scania, Mercedes-Benz, Iveco, Renault, Isuzu, Fuso, MAN, DAF and many more. Our dedicated design department continually develops and refines our plant bodies to ensure perfect compatibility with the latest vehicle models across all leading brands.

Select a filter to start browsing or click here to view all.

Contact our specialist plantbody team to tailor one for you today.

Call Us: 01264 358 944No matter how bespoke your requirement, we're confident we can design a trailer for the task. We've built trailers for transporting everything from huge radar equipment to nuclear waste containers, and from boats to railway locomotives.

Our engineering team thrives on solving unique transportation challenges. Whether you're moving oversized, delicate, or highly specialised cargo, we can work with you to develop a custom trailer that exceeds expectations.

Every bespoke project is a collaboration—our experienced design and manufacturing teams take your requirements and turn them into precision-built solutions, optimised for performance, safety, and efficiency.

If you can describe it, we can build it. Our advanced design systems and flexible manufacturing allow us to create trailers for industries and applications across the globe. From one-off custom builds to complex multi-unit fleets, we deliver without compromise.

Speak to our bespoke engineering team to design a custom trailer built around your needs.

Call Us: 01264 358 944Armed forces across the world have exacting requirements, and Andover Trailers is particularly well equipped to meet these—whatever their trailer need may be.

From logistics support to specialist recovery and launch platforms, we have decades of experience supplying bespoke equipment to military organisations and their transport providers.

Whether it's moving armoured vehicles, launching drones, or performing multi-mode recovery operations, our trailers are engineered for the most demanding conditions—both on-road and off-road.

We design and manufacture to spec. If you need it, we can build it.

Our team has the expertise to deliver a trailer for even the most demanding military environments.

Call Us: 01264 358 944The EU Tyre Labelling system is designed to provide consumers with essential information about tyre performance, making it easier to compare different options and make informed purchasing decisions. Introduced to improve safety, fuel efficiency, and environmental impact, the label evaluates tyres across three key categories:

Information on these figures can be found on the European Commission website on tyre labelling regulations:

https://energy-efficient-products.ec.europa.eu/product-list/tyres_en

Further information on your choice of tyre is available from your Andover Trailers representative. If your chosen tyre is not listed below, please contact us for details.

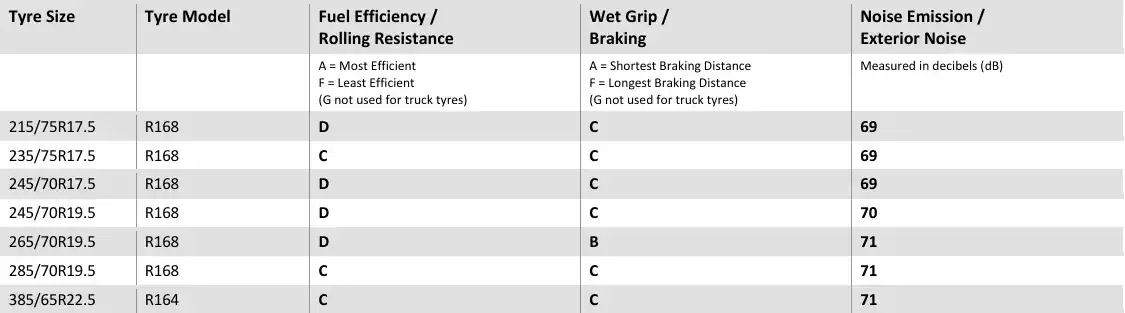

Bridgestone

For more information on Bridgestone tyres, please visit:

https://www.bridgestone.co.uk/truck-and-bus

For more information on Bridgestone tyres, please visit:

https://www.bridgestone.co.uk/truck-and-bus

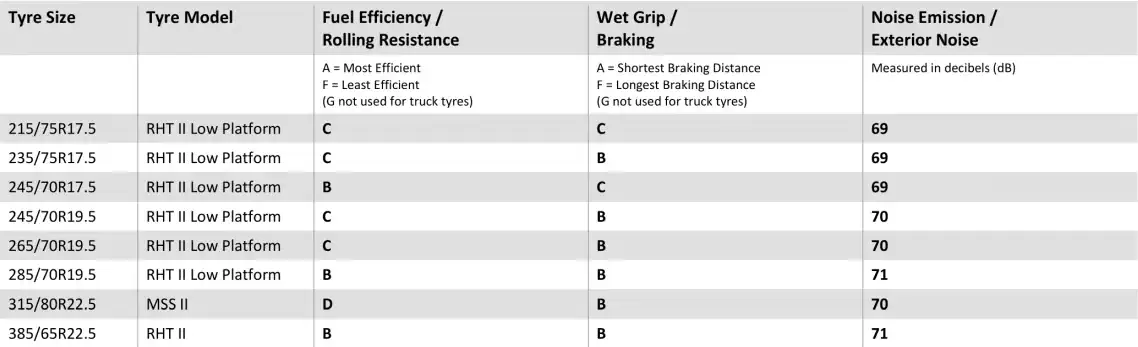

Goodyear

For more information on Goodyear tyres, please visit:

https://www.goodyear.eu/en_gb/truck/tyres.html

For more information on Goodyear tyres, please visit:

https://www.goodyear.eu/en_gb/truck/tyres.html

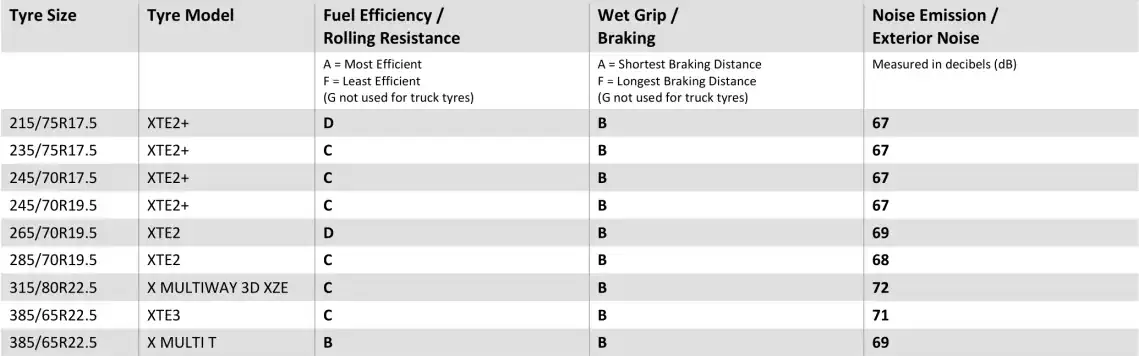

Michelin

For more information on Michelin tyres, please visit:

https://business.michelin.co.uk/freight-transport

For more information on Michelin tyres, please visit:

https://business.michelin.co.uk/freight-transport

Our technicians are trained to inspect, maintain, and repair every critical component of your trailer or plant body.

Inspection, replacement, and inflation to maintain safety and efficiency.

Full brake checks and adjustments to keep your fleet roadworthy.

Replacement and fault diagnosis for trailer and plantbody lighting systems.

We assess and service air and leaf spring systems.

Repair of wiring, plugs, control units, and other components.

Hydraulic system diagnostics, maintenance, and fluid checks.

We support a wide range of trailer and bodywork components — just ask our team.

We work closely with industry leaders to ensure our customers have access to round-the-clock support, wherever they are.

We work with trusted service partners across the UK. Find your nearest service point below.

Our friendly service team is here to help with any issues or questions you may have.

We supply a comprehensive range of parts for all Andover trailers and plant bodies — and more.

All components are engineered to match your trailer or body, ensuring perfect fit and performance.

We also stock compatible parts for other brands of commercial and industrial equipment.

Collect in person or choose fast, reliable shipping — we make getting the right part simple.

Our friendly team is here to help you!

All Andover Trailers products are covered by a 12-month manufacturer's warranty, starting from the date of delivery. We guarantee your trailer will meet the specifications ordered and be free from material or workmanship defects.

✓ 12-month warranty against faulty materials or poor workmanship

✓ Repair or replacement of defective parts at no cost

✓ Manufacturer-backed guarantees on bought-in components (subject to registration)

✗ Damage caused by overloading, misloading, or excessive speed

✗ Alterations or additions made outside of our factory

✗ Parts or equipment not sold or approved by Andover Trailers

✗ Costs of dismantling, transport or reinstallation

Give our friendly team a call and we will answer all questions you might have!

Enter your manual access code:

Andover Trailers Ltd

75 Columbus Way

Walworth Business Park

Andover

Hampshire

SP10 5NP

United Kingdom

☏ +44 (0) 1264 358 944

☏ +44 (0) 1264 358 944

✉ sales@andovertrailers.co.uk

☏ +44 (0) 1264 322 445

✉ service@andovertrailers.co.uk

☏ +44 (0) 1264 322 445

✉ parts@andovertrailers.co.uk

Andover Trailers Limited is registered in England and Wales.

Company Registration: 2783047

VAT Number: GB 631 5204 78